Everywhere I go, I see objects made of recycled tire rubber. I can’t help but smile every time because I think this is a sort of “professional distortion”: as a professional in the tire recycling business, I tend to see the world through the lenses of my work experience, noticing things that other people do not even see. Talking with people around me, however, I have realized that there is little awareness of how many new products can be manufactured starting with the rubber coming out of the tire recycling process, and how broad their fields of application can be. The world of tire-derived moulded goods is a universe of which we have not come to know the borders yet.

The journey from tires to recycled rubber moulded goods starts with waste: when a tire reaches the end of its life, it needs to be properly disposed of and this often implies going through a shredding process. In this phase, rubber is separated from a tire’s other components and reduced into granulate. This rubber granulate, also known as rubber crumb, is no longer a waste but a valuable secondary raw material that, thanks to a transformation process, gives tires a new life.

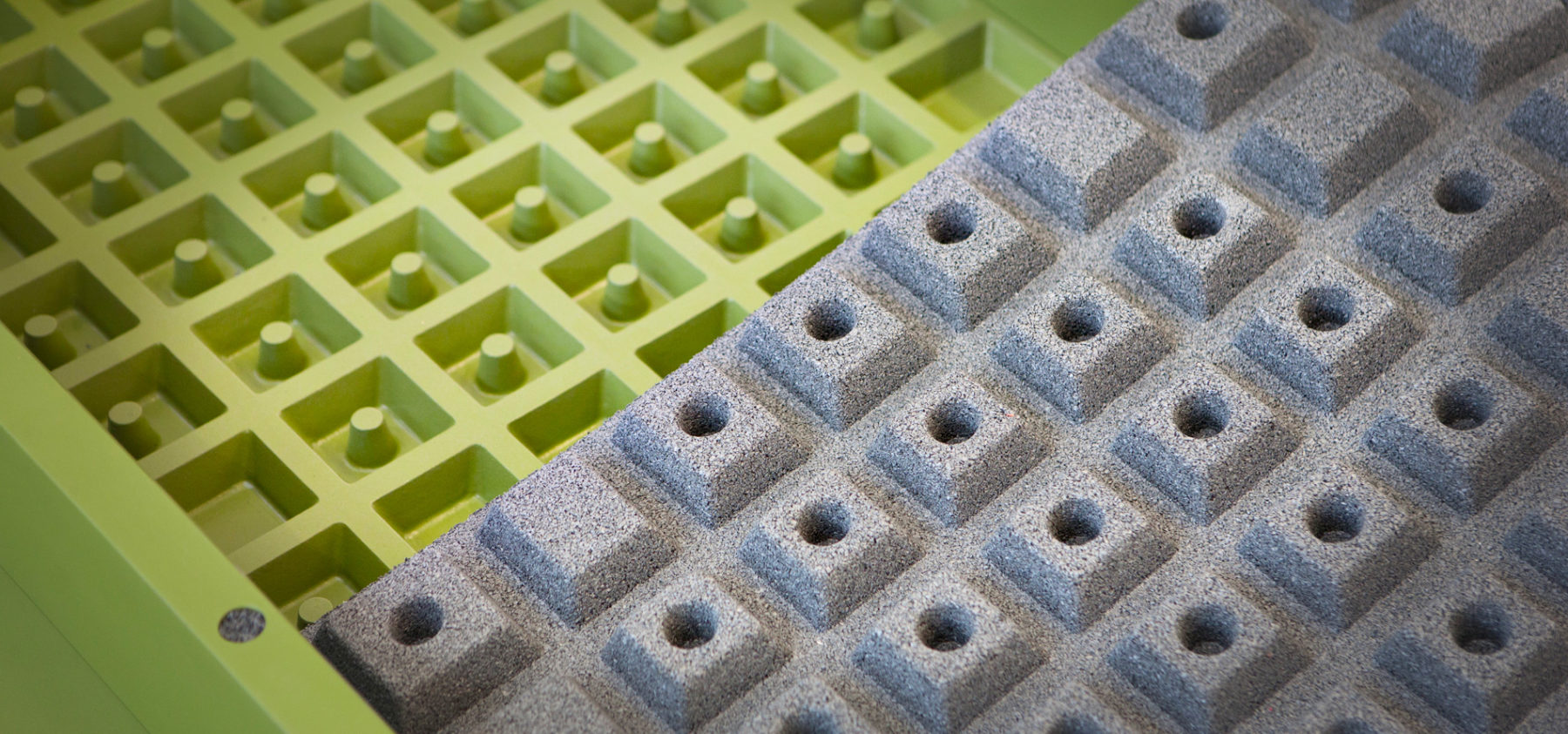

The technology to produce tire-derived moulded goods has been on the market for more than 20 years and it is thus consolidated. Its maturity together with the relatively low investment level makes it a technology accessible to small companies as well. But how does it work? The recycled rubber crumb is mixed with a polyurethane binder coming in liquid form, which is usually around 8% to 10% of the weight of the rubber granulate. In case the final product needs to have a color other than black, color may be added to the mix. A small amount of water is also inserted because the humidity is the real trigger for the binder to start reacting. The mix is then unloaded into a press equipped with a mould and subject to constant pressure where it takes the desired shape.

The production process can be hot or cold. We speak about a hot process when heat is added during the pressing phase: this usually happens thanks to some electrical heatings and is used in the production of most moulded goods. While heat is not necessary for the binder to react, it speeds up the process and allows for a higher output rate.

A cold process is used when the goods to be manufactured are too thick to allow the heat to evenly spread through the product, reaching its inner part as well. Once the mix of rubber and binder has been unloaded into the mould and pressed, it needs to rest until the binder has completely cured, which may take up to 24 hours depending on the binder used, product’s thickness, and room temperature.

The basic production process is simple: a mixer and a press are the only pieces of equipment you will need if you want to produce moulded goods starting with recycled tire rubber crumb. If, however, you want to industrialize the system to make it a profitable business, you should invest in equipment that allows you to automatize the process and increase your productivity.

For example, adding PLC control to the mixer guarantees an accurate weight dosing of all components that translates into a consistent and high quality of the finished goods. Additionally, the possibility to track all production data is key when understanding how to adjust the mix to improve some specific qualities or simply when facing possible customer claims. The same ratio applies to the press: by checking working pressure and heat the producer knows in advance if the resulting moulded goods will respect the quality parameters and will also be able to prevent possible failures of the machine, intervening promptly and reducing downtime.

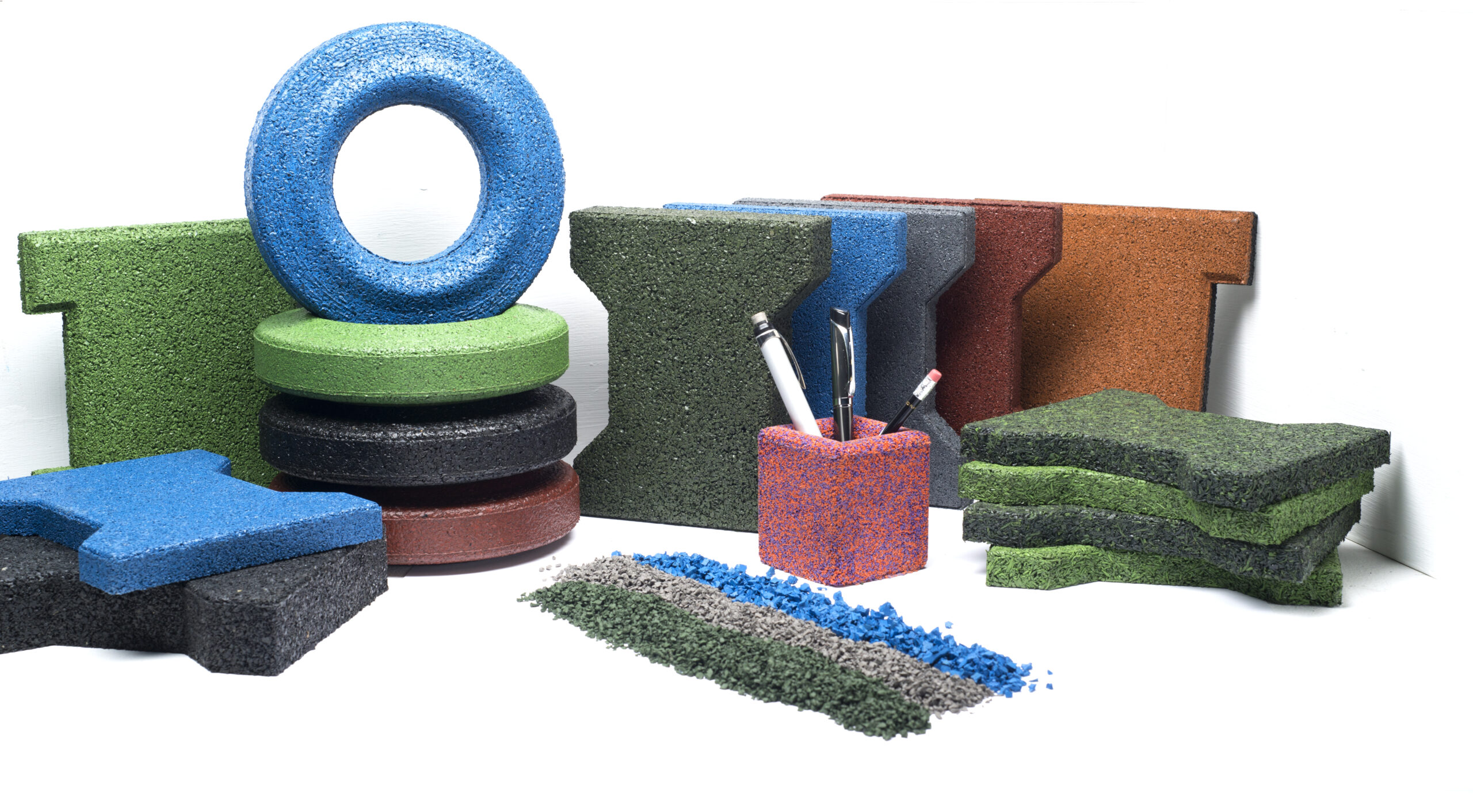

Tire-derived moulded goods have an incredibly wide range of applications thanks to rubber’s excellent noise, shock, and vibration damping characteristics. The industry covered are playground and leisure equipment, commercial and industrial flooring, traffic and safety, flooring for livestock, construction, and infrastructure. The most famous examples are the anti-shock tiles installed in children’s playgrounds to reduce the possible impact of a child falling on the ground but there is much more. If we look at our roads, we can find speed bumps, safety barriers, and supports for road signs that are often made of recycled rubber, making them a greener and cheaper alternative to those manufactured with virgin material. When we go to the gym, the flooring is covered with rubber tiles made of recycled rubber and the bumper plates we use for weightlifting are probably made of it, too. In apartment buildings, the insulating layer is of recycled rubber because it reduces the propagation of vibration and noise from one floor or apartment to the other. Anti-seismic devices made of recycled rubber have been developed to lower the risk of damage during earthquakes.

The industry has been experiencing steady growth over the last few years, boosted by the general trend towards a circular economy. New applications are constantly being developed but until now, none of them has proved to be a potential game changer. Every year, more and more tires reach the end of their life and the amount of recycled rubber generated is so big that until now, it cannot be absorbed by the existing range of moulded goods. To exploit this hidden potential, different players must come together to innovate: technology providers, companies operating with vibration and noise damping systems, universities and circular economy experts must cooperate to find new high-volume applications in which recycled rubber offers superior performance staying competitive with the price. This, together with the research for alternative ways to eliminate or reduce the use of PU binders in the process to lower production cost, is probably the major technical challenge we need to face. The other challenge we have is fighting the still circulating mentality of “new is better performing” and “tires are a waste I don’t care about”: we are all equally responsible for taking care of our planet and this means also taking advantage of used material without always extracting new ones. If we become 100% aware of this, we will naturally undergo a mental shift that will lead us to start seeing opportunities in the strangest places. This will no longer be the “professional distortion” of a single person but a widespread common mindset that will ultimately be our ticket to change.

PDF file: A ticket to change: tire-derived moulded goods manufacturing